Why Manufacturers Are Adopting Pre-Certified Lighting for L-Category Vehicles in Europe|BRIGHTSTARTW Mobility Insights

Pre-certified lighting is becoming a critical requirement for L-category vehicles as electric scooters, three-wheelers, and lightweight four-wheel mobility platforms enter the European market. As lighting homologation grows increasingly complex, early adoption of compliant lighting systems helps manufacturers reduce regulatory risks and accelerate approval timelines.

Lighting systems consistently account for the highest homologation failure rate due to stringent ECE requirements. As a result, more mobility brands are turning toward compliant lighting modules to ensure predictable performance and EU-grade reliability.

This article provides a structured overview of:

. Why early integration of certified lighting components benefits manufacturers

. Key lighting regulations for L-category vehicles in Europe

. The major advantages that compliant lighting brings to vehicle manufacturers

. How BRIGHTSTARTW supports mobility brands in achieving efficient, low-risk market entry

Manufacturers adopting validated lighting systems can streamline development and significantly reduce homologation variability.

1. Technical Rationale for Early Integration

A certified lighting module is a pre-approved lighting unit that has already passed ECE / E-Mark tests for optical performance, EMC, waterproofing, durability, and marking requirements. Because the optical system is pre-validated, manufacturers can install these units directly and proceed to vehicle-level homologation without additional optical testing.

The following sections summarize the main engineering and regulatory advantages.

1.1 Accelerating Vehicle Development Schedules

Without validated lighting components, vehicle manufacture must conduct optical testing, adjust beam patterns, resubmit samples, and wait for approval—delays that directly affect homologation timelines.

. Optical and photometric testing can be bypassed

. Vehicle homologation can proceed without system redesigns

. Development delays caused by test failures are eliminated

For brands operating under fixed seasonal launch windows, even a one-month acceleration can provide significant competitive advantage.

1.2 Reducing Engineering and Certification Costs

Developing a lighting system from scratch requires substantial investment, including optical design, tooling, EMC testing, waterproof validation, and durability verification.

Using homologation-ready modules enables vehicle manufacture to:

. Avoid multiple prototype rounds and repeated test submissions

. Maintain predictable development expenses

. Lower engineering time and certification-related costs

This approach is particularly beneficial for fast-moving EV startups and compact R&D teams.

1.3 Improving Homologation Approval Rates

Lighting systems are one of the most common causes of homologation rejection in L-category vehicles. Typical issues include:

. Beam angle or intensity deviations

. Incorrect or incomplete E-marking

. Improper DRL and low-beam switching logic

. Incorrect mounting height or orientation

Using certified systems removes these uncertainties and provides a solid foundation for predictable, repeatable homologation outcomes.

1.4 Enhancing System Reliability for EU Markets

European markets enforce strict safety and lighting performance requirements. Lighting defects frequently trigger product recalls and regulatory actions. Common failure modes include:

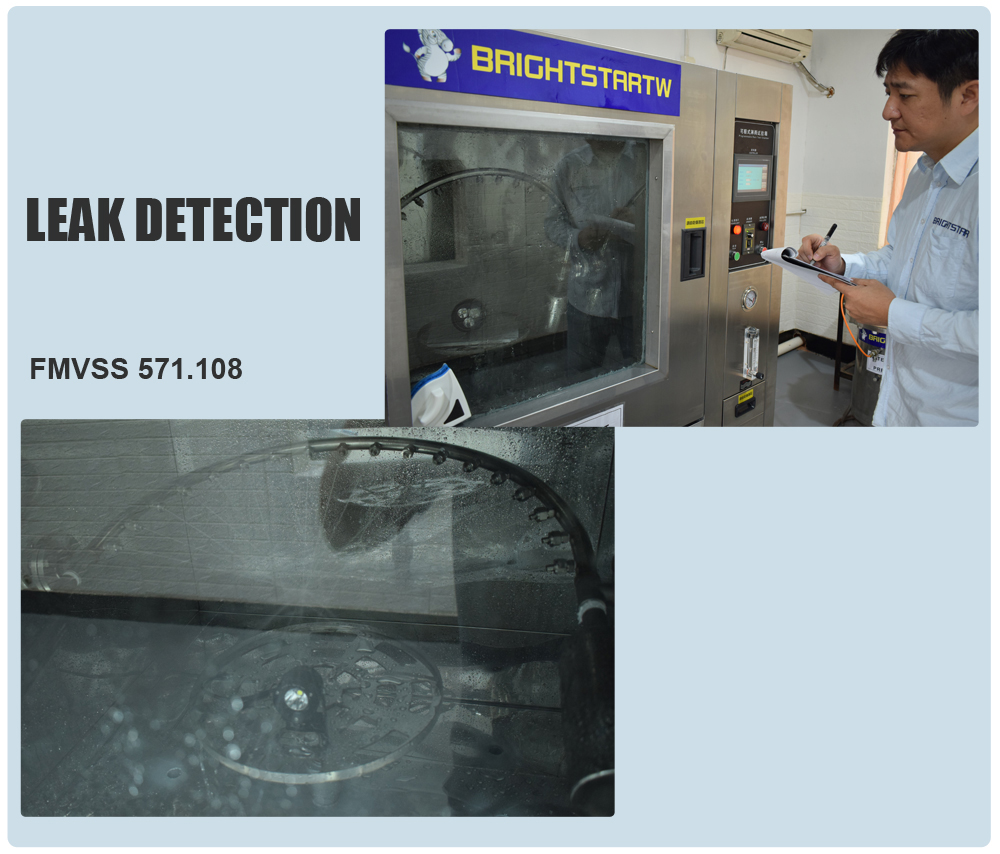

. Insufficient illumination or excessive glare

. Water ingress or condensation

. Environmental durability issues

. EMC interference affecting control electronics

Certified components dramatically reduce the likelihood of post-launch failures and strengthen long-term brand reliability.

2. Key Regulatory Requirements for L-Category Lighting

L-category vehicles (L1e–L7e), including scooters, mopeds, trikes, micro EVs, and lightweight quadricycles, must meet European ECE lighting standards.

2.1 Relevant ECE Regulations

● Front direction indicator: ECE R50

● Rear direction indicator: ECE R50

● Headlamp (low/high beam): R112 / R113 / R149

● DRL – Daytime Running Lamp: R87

● EMC – Electromagnetic Compatibility: R10

2.2 Installation Constraints Affecting System Performance

Even when using compliant modules, the installation itself must satisfy ECE criteria:

● Correct mounting height, lateral distance, and longitudinal position

● Proper headlamp angle and beam alignment

● DRL to low-beam switching requirements

● No interference between running lights, indicators, and DRLs

● Fulfillment of anti-glare and illumination thresholds

Early adoption helps manufacturers finalize packaging, wiring, and integration much earlier, reducing late-stage design iterations.

Since compliant modules already meet performance standards, engineering adjustments during homologation are minimized.

3. Advantages for vehicle manufacture Using Certified Lighting Systems

Below is a technical summary of the benefits commonly highlighted during vehicle manufacture consultation projects.

3.1 Reduced Certification Complexity

By eliminating optical certification steps, manufacturers avoid redesign loops, prototype delays, and retesting cycles.

3.2 More Predictable Project Costs

Certified components already meet E-Mark standards, reducing the need for multiple tooling modifications, optical adjustments, and repeated compliance testing.

3.3 Higher Approval Rates During Vehicle Homologation

Using validated modules ensures stable lighting characteristics and helps vehicle manufacture maintain high first-pass approval rates.

3.4 Proven Durability for EU Road Conditions

● Waterproofing and temperature resistance

● Stable optical output

● EMC compliance

● Long-term reliability validation

These characteristics are essential for long-term use in European micro-mobility environments.

3.5 Lower Risk of Recalls and Regulatory Issues

With lighting systems already tested and validated, vehicle manufactures experience fewer compliance-related issues after market entry.

For companies targeting Europe’s micro-mobility sector, using compliant lighting modules offers the most efficient path to regulatory readiness.

Conclusion: A Strategic Pathway to Faster EU Market Entry

For manufacturers operating under tight development cycles and strict European regulations, using validated lighting components is a practical and impactful strategy for reducing risk, controlling cost, and accelerating time-to-market.

BRIGHTSTARTW supports vehicle manufacture and mobility brands with robust, regulation-compliant lighting solutions engineered for reliable vehicle development and successful homologation.

● UNECE Official Regulations — https://unece.org/transport/vehicle-regulations

● EU Vehicle Compliance Guidelines — https://europa.eu/youreurope/business/product-requirements/index_en.htm

●Vehicle Regulations —://unece.org/transport/vehicle-regulations

About BRIGHTSTARTW

BRIGHTSTARTW provides complete optical design expertise, durability engineering services, and regulatory certification support. Our team helps vehicle manufacturers build compliant, high-performance lighting systems tailored for next-generation Speed Pedelec and electric mobility solutions.

📩 Contact us: [email protected]